Über uns

On this page, we provide important documents for downloading.

Brochure

Find our current company presentation as a PDF file here: Brochure.

Terms and Conditions

Find our current terms and conditions here: Terms and conditions.

Our motivated employees produce stainless steel vessels and apparatus on modern machinery, adhering to highest quality standards .

Quality, Motivation, Innovation

To meet the high quality standards of our customers, stringent separation of carbon and stainless steel is both an indispensable codex and a reality at AMS.

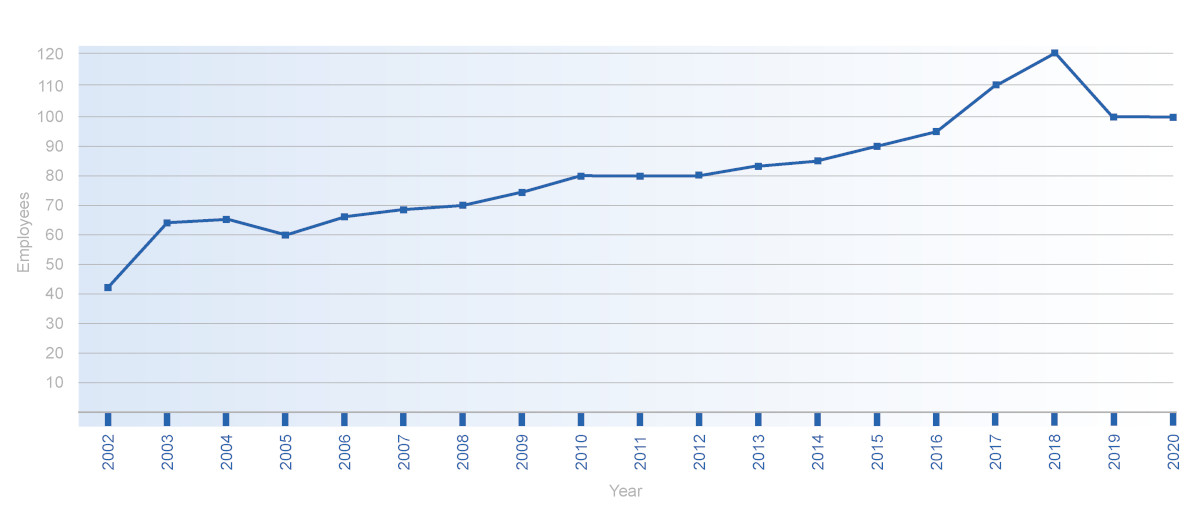

Our staff of 100 employees at AMS Technology is working tirelessly to further increase quality standards. This helps us to manufacture vessels and apparatus of highest quality. Thus, we can always fulfil the constantly rising demands regarding life cycle load resistance at different temperature ranges and different pressure characteristics as well as the increasing purity demands of our customers in the biotechnology, cosmetics, pharmaceutical and food industries.

Our team's experience and dedication facilitated the transition from a wooden barrel washing machine manufacturer in the early 60’s to the company we are today: A specialist for apparatus and vessels made from stainless steel. A key aspect of our personnel policy is in-house training with a permanent number of 10‒12 apprentices. Our aim is to integrate each of our apprentices into the company after the completion of their training.

Additionally, work-study programmes in the areas Design and Production Technology guarantee a constant mutual transfer of experience and innovation. Because of AMS Technology's continuous growth since 2002, we had the ability to more than double the size of our company in terms of staff. Find out more about the history of our company on the page Milestones.

From a manufacturer of wooden barrel washing machines to a highly technical specialized vessel and apparatus developer and manufacturer.

Follow our evolution from a wooden barrel washing machines manufacturer to a specialized vessel and apparatus producer.

Timeline

| 2018 |

|

| 2017 |

|

| 2016 |

|

| 2015 |

|

| 2014 |

|

| 2013 |

|

| 2012 |

|

| 2011 |

|

| 2010 |

|

| 2008 |

|

| 2007 |

|

| 2006 |

|

| 2005 |

|

| 2004 |

|

| 2003 |

|

| 2002 |

|

Historical Development

In the early 60’s, AMS Technology’s predecessor manufactured wooden barrel washing machines in Limbach-Oberfrohna. By the end of the 60’s, technology advanced and the company started to move from wooden onto stainless steel products. At the begin of the 70’s, the company had stopped manufacturing wooden products. It also started expanding into supplying components for textile finishing. Until the end of the 80’s it further diversified its product range by developing and manufacturing own dying mill machines.

Following the German reunification and the political changes in 1989, the Saxon textile industry collapsed. The company was looking for new paths and product ranges and it seemed that vessel and appliance production might be the answer. Under the name Aurich Edelstahl GmbH, the company innovated in the field of vessel and appliance production.

On July 2, 2002, OMEGA Blechbearbeitung GmbH took over the business and founded AMS Technology GmbH. AMS was integrated into the OMEGA group of companies and has since enriched the group’s product portfolio. Thus, the OMEGA group could now offer everything from sheet metal processing to machining to stainless steel appliance production.

At the time of the takeover, the business employed 42 staff. Since then, AMS not only continuously increased its turnover but also more than doubled its size in terms of staff. Apprenticeships always were and still are the corner stone of the company's personnel policy. Currently, the company trains two apprentices per year with the aim of integrating them into the business on completion of their course.

The continuous growth of the company meant that it could begin the construction of purpose-built premises. Being so close to the A72 / A4 motorway junction, the industrial park Süd just outside of Limbach-Oberfrohna promised ideal transport links. The move from the old rented premises in the Waldenburger Strasse in Limbach-Oberfrohna was completed by February 6, 2006.

Good business and full books meant that, within two years, the company could expand its facilities to double the production capacity from 3,100 m2 to 6,200 m2.