Leistungen

Configuration, Optimization, Planning

The complex nature of our client’s machines define the demands of day-to-day production. The constraints and requirements change according to the machine.

If you wonder how to integrate process components such as stirring units, CIP vessels, heat exchangers or storage vessels into planned or existing machines, AMS Technology is happy to advise you on your job specification. Among others things, we have advised clients on:

- Wall thickness optimisation (saving material)

- Choice of alloy

- Surface finishing (polished or ground)

- Optimum cooling or heating options

- Insulation in accordance with requirements

- Appropriate installation options

- Maintenance

- Cleaning

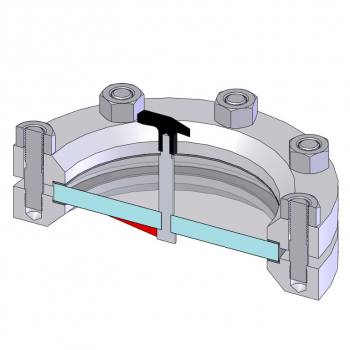

Stainless Steel Processing

We are your competent partner in all matters of professional and high quality stainless steel processing in the field of vessel, apparatus and plant construction.

We can support you with our entire experience, design to your requirements and implement designs.

Do you need custom-built products from stainless steel, require design services or need components pickled? You have come to the right place.

AMS Technology stands for stainless steel processing with highest precision and quality. Use our experience with stainless steel and our technology to process it.

We Engineer and Design Your Complete Plants.

In-house design department for vessels, apparatus and plants…

Our design engineers for vessel, apparatus and appliance construction, draftsmen, detail designers and technical writers construct, calculate, draw and document everything according to your job specification, providing drawings and/or safety-related requirements. Our designs are created using a number of 3D and 2D systems.

Design software

We own construction software for the 2D- and 3D-construction.

3D tools

- Autodesk Inventor Professional

2D tools

- AutoCAD Mechanical

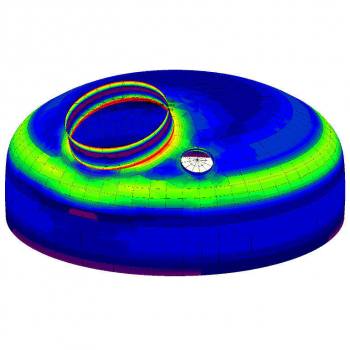

Dimensioning of pressurized vessels or appliances

The dimensioning of pressurized vessels or appliances is carried out with:

- WIN_SHELL

- COMPRESS

Documentation

Documentation requirements are especially strict in the food and pharmaceutical industries. Hence, a technical writer is part of our design team. Our Documentation department is in direct contact with our quality assurance, acceptance and approval organisation (technical control board (TÜV North, TÜV South, TÜV Thuringia, Germanischer Lloyd, TSSA and many more) and external service providers (e. g. for non-destructive tests, welding procedure qualifications and material examinations) and our customers, of course.

Contents of Documentation

- Operation and maintenance instructions

- Material quality certificates

- Production and calculation logs

- Risk analysis

- Proofs for surface roughness values

- X-ray logs

- Technical acceptance and test logs

- Proof of interstice examinations with video endoscope in inaccessible areas

- Proof of the materials used

Machining, Cutting, Pickling, Grinding, Polishing

Are you looking for production capacities in stainless steel processing? We offer you:

- Machining of stainless steel parts

- 3D plasma cutting with robot

- Dunk and spray pickling of stainless steel parts

- Grinding works on stainless steel parts

We Design and Fabricate for You

We manufacture stainless steel parts and assemblies according to your production or project requirements: fast, reliable and without red tape. We are also the right company for you if you require engineering services with subsequent production.

We Machine for You

We are happy to carry out all your stainless steel turning, milling and drilling jobs. Just one glance at our equipment list will convince you.

We Cut for You

Our plasma cutting robot enables 3-dimensional hole and bevelling cuts. Two mobile cutting tables that can be moved either separately or in unison allow cutting of vessel heads and flat metal sheets with a maximum total size of 4,270 x 4,120 mm (14 x 13.5 ft). Use the efficiency and precision of that machine.

We Pickle for You

Do you want your components to be acid cleaned with our spray system or in our dip tank? Not a problem. We are also happy to assist you when deciding on the right choice of stainless steel alloy.

We Grind and Polish for You

We have more than ten manual working spaces for individual grinding and polishing works available. Modern belt grinding machines are used for the internal and external grinding of vessels and heads as well as for the execution of cylindrical grinding works. A double belt grinding machine is installed for grinding, matting and polishing flat surfaces.